My Garage

My Account

Cart

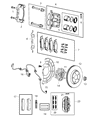

Genuine Dodge Durango Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

53 Brake Discs found

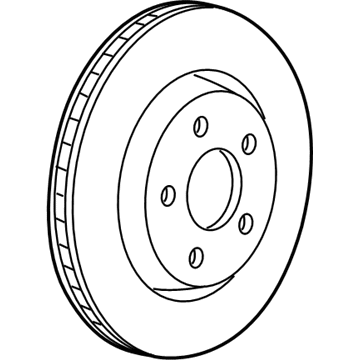

Dodge Durango Disc Brake Rotor Front

Part Number: 68035012AE$144.25 MSRP: $222.00You Save: $77.75 (36%)

| Page 1 of 3 |Next >

1-20 of 53 Results

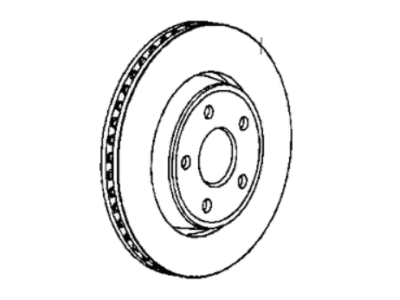

Dodge Durango Brake Disc

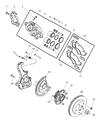

The Brake Disc in Dodge Durango cars is the component that comprises disc brake system where brake pad rub against to reduce or bring the car to a halt. As you will notice, it is attached to the axle or the hub and it rotates with the wheel where hydraulic pressure from the caliper presses the pad against the rotor when you are braking. Durango models may have one or another type of rotors depending on their construction: some of the rotors are solid while others are vented although the latter contain special fins for cooling. Some signs that indicate that Brake Discs need to be replaced include warpage, which can distort the Brake Disc and, therefore, affect braking efficiency or thinning which reduces the material that can be used in braking and corrosion that can cause the Brake Discs to rust and, thereby, lose efficiency. Fundamental to this is the practicality of routine inspections because the rotors have to meet minimum thickness standards for them to work properly. The wear can be partially corrected by machining the shafts and it is generally good practice to replace rotors in pairs for safety and performance reasons. In general, the Brake Disc should be maintained to warrant capable brake operation in Dodge Durango automobiles.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Durango Brake Disc at great affordable prices. Moreover, all genuine Dodge Durango Brake Disc come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Durango Brake Disc Parts Questions & Experts Answers

- Q: How Do You Remove and Install a Brake Disc on Dodge Durango?A:Loosen the wheel lug nuts, raise the vehicle and support it securely on jackstands. Apply the parking brake. Remove the wheels. Visually inspect the disc surface for score marks and other damage. Light scratches and shallow grooves are normal after use and won't affect brake operation. Deep grooves require disc removal and refinishing by an automotive machine shop. Be sure to check both sides of the disc. To check disc run out, place a dial indicator at a point about 1/2-inch from the outer edge of the disc. Install the lugnuts, with the flat sides facing in, and tighten them securely to hold the disc in place. Set the indicator to zero and turn the disc. The indicator reading should not exceed the run out limit. If it does, the disc should be refinished by an automotive machine shop. If you elect not to have the discs resurfaced, deglaze them with sandpaper or emery cloth. The disc must not be machined to a thickness less than the specified minimum thickness, which is cast into the disc. The disc thickness can be checked with a micrometer. Remove the Brake Caliper (don't disconnect the brake hose) and hang it out of the way. Remove the caliper mounting bracket. Remove the lug nuts installed and pull the disc off the hub. If the disc is held in place by pressed on washer-like retainers, cut them off. Installation is the reverse of removal. Tighten the caliper mounting bracket fasteners to the torque. Lower the vehicle and tighten the wheel lug nuts to the torque.

Related Dodge Durango Parts

Browse by Year

2023 Brake Disc 2022 Brake Disc 2021 Brake Disc 2020 Brake Disc 2019 Brake Disc 2018 Brake Disc 2017 Brake Disc 2016 Brake Disc 2015 Brake Disc 2014 Brake Disc 2013 Brake Disc 2012 Brake Disc 2011 Brake Disc 2009 Brake Disc 2008 Brake Disc 2007 Brake Disc 2006 Brake Disc 2005 Brake Disc 2004 Brake Disc 2003 Brake Disc 2002 Brake Disc 2001 Brake Disc 2000 Brake Disc 1999 Brake Disc 1998 Brake Disc