×

- Live Chat

- 1-888-511-3595

My Garage

My Account

Cart

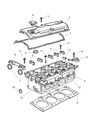

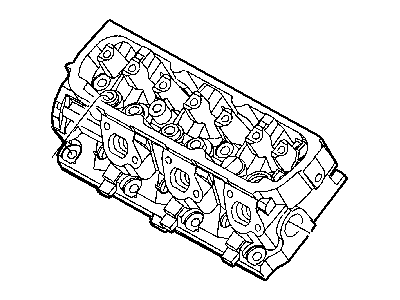

Genuine Dodge Grand Caravan Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

59 Cylinder Heads found

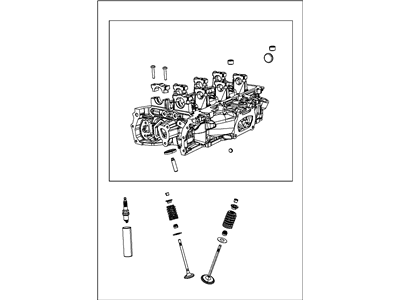

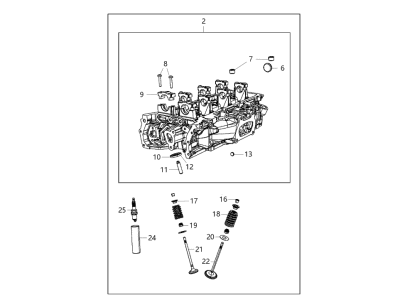

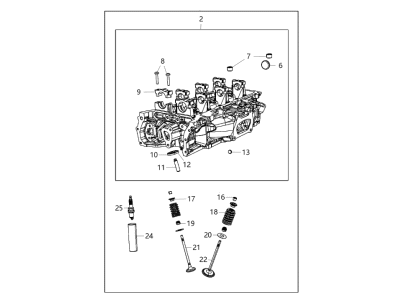

Dodge Grand Caravan Head&Valve-Cylinder

Part Number: 68141352AD$609.17 MSRP: $1025.00You Save: $415.83 (41%)Dodge Grand Caravan Head-Cylinder

Part Number: R5633411AB$852.35 MSRP: $1035.00You Save: $182.65 (18%)Dodge Grand Caravan Head-Engine Cylinder

Part Number: 68141353AB$986.97 MSRP: $1155.00You Save: $168.03 (15%)Dodge Grand Caravan Head-Cylinder

Part Number: RL141353AB$986.97 MSRP: $1155.00You Save: $168.03 (15%)Dodge Grand Caravan Head&Valve-Cylinder

Part Number: 68141352AE$609.17 MSRP: $1025.00You Save: $415.83 (41%)Dodge Grand Caravan Head-Cylinder

Part Number: 68141352AB$609.17 MSRP: $1025.00You Save: $415.83 (41%)Dodge Grand Caravan Head-Engine Cylinder

Part Number: RL141352AB$609.17 MSRP: $1025.00You Save: $415.83 (41%)Dodge Grand Caravan Head&VALV-Cylinder

Part Number: R3602014AA$701.30 MSRP: $1065.00You Save: $363.70 (35%)Dodge Grand Caravan Head&VALV-Cylinder

Part Number: R3620113AA$686.24 MSRP: $835.00You Save: $148.76 (18%)Dodge Grand Caravan Head&VALV-Cylinder

Part Number: R3620112AA$597.09 MSRP: $696.00You Save: $98.91 (15%)Dodge Grand Caravan Head-Cylinder

Part Number: 4694686AA$951.63 MSRP: $1110.00You Save: $158.37 (15%)Dodge Grand Caravan Head-Cylinder

Part Number: R5424847$1109.70 MSRP: $1345.00You Save: $235.30 (18%)

| Page 1 of 3 |Next >

1-20 of 59 Results

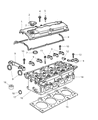

Dodge Grand Caravan Cylinder Head

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Grand Caravan Cylinder Head at great affordable prices. Moreover, all genuine Dodge Grand Caravan Cylinder Head come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Grand Caravan Cylinder Head Parts Questions & Experts Answers

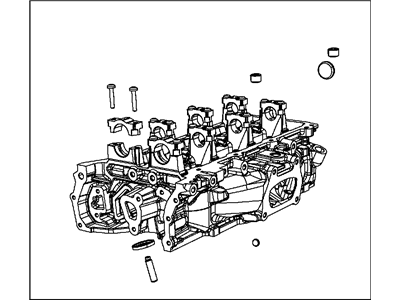

- Q: What precautions should be taken before beginning the cylinder head replacement procedure on Dodge Grand Caravan?A: Allow the engine to cool completely before beginning this procedure. Position the number one piston at Top Dead Center. Disconnect the negative cable from the battery. Drain the cooling system and remove the spark plugs. Remove the intake/exhaust manifold; if only replacing the cylinder head gasket, it isn't necessary to remove the manifolds, but assistance may be needed to lift the head off the engine if the manifold is left attached. Remove the distributor, including the cap and wires. Remove the Timing Belt. Remove the valve cover. Loosen the head bolts in 1/4-turn increments until they can be removed by hand, following the recommended sequence to avoid warping the head. Lift the head off the engine, taking care not to pry between the head and block gasket mating surfaces to avoid damage; instead, pry against the casting protrusions on the sides of the cylinder head and set the head on blocks of wood to prevent damage to the gasket sealing surfaces. Cylinder head disassembly and inspection procedures are important, and it's advisable to have the head checked for warpage, even if just replacing the gasket. The mating surfaces of the cylinder head and block must be perfectly clean when the head is installed. Use a gasket scraper to remove all traces of carbon and old gasket material, then clean the mating surfaces with lacquer thinner or acetone. If there's oil on the mating surfaces when the head is installed, the gasket may not seal correctly and leaks may develop. Stuff the cylinders with clean shop rags to keep out debris while working on the block, and use a vacuum cleaner to remove any material that falls into the cylinders. Since the head is made of aluminum, be careful not to damage the mating surfaces with aggressive scraping. Check the block and head mating surfaces for nicks, deep scratches, and other damage; slight damage can be removed with a file, while excessive damage may require machining. Use a tap of the correct size to chase the threads in the head bolt holes, and mount each head bolt in a vise to run a die down the threads to remove corrosion and restore them, as dirt, corrosion, sealant, and damaged threads will affect torque readings. Place a new gasket on the block and set the cylinder head in position. Install the bolts, tightening them in four steps while following a specific sequence to the required torque. Reinstall the timing belt. Reinstall the remaining parts in the reverse order of removal. Be sure to refill the cooling system and check all fluid levels. Rotate the crankshaft clockwise slowly by hand through two complete revolutions and recheck the Camshaft timing marks. Start the engine and check the ignition timing. Run the engine until normal operating temperature is reached, checking for leaks and proper operation.

Related Dodge Grand Caravan Parts

Browse by Year

2020 Cylinder Head 2019 Cylinder Head 2018 Cylinder Head 2017 Cylinder Head 2016 Cylinder Head 2015 Cylinder Head 2014 Cylinder Head 2013 Cylinder Head 2012 Cylinder Head 2011 Cylinder Head 2010 Cylinder Head 2009 Cylinder Head 2008 Cylinder Head 2007 Cylinder Head 2006 Cylinder Head 2005 Cylinder Head 2004 Cylinder Head 2003 Cylinder Head 2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1995 Cylinder Head 1994 Cylinder Head 1993 Cylinder Head 1992 Cylinder Head 1991 Cylinder Head 1990 Cylinder Head 1989 Cylinder Head 1988 Cylinder Head 1987 Cylinder Head