My Garage

My Account

Cart

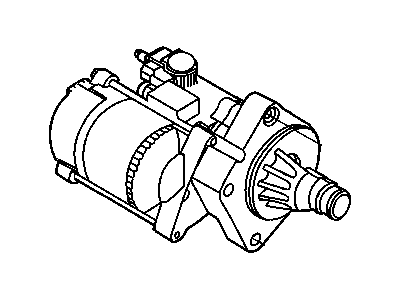

Genuine Dodge Grand Caravan Starter Motor

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

30 Starter motors found

Dodge Grand Caravan Starter-Engine

Part Number: 4801839AD$276.98 MSRP: $417.00You Save: $140.02 (34%)

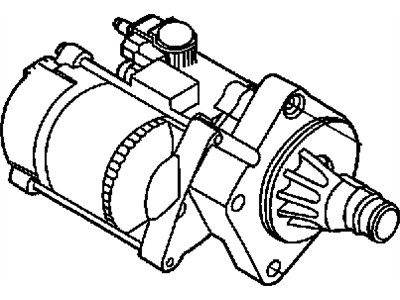

Dodge Grand Caravan Engine Starter

Part Number: 4608800AE$349.52 MSRP: $510.00You Save: $160.48 (32%)

Dodge Grand Caravan Starter Motor

Part Number: R4608800AE$225.45 MSRP: $266.00You Save: $40.55 (16%)

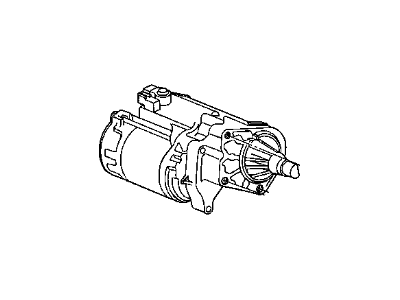

Dodge Grand Caravan Starter-Engine

Part Number: 4801839AC$276.98 MSRP: $417.00You Save: $140.02 (34%)

Dodge Grand Caravan Engine Starter

Part Number: RL801839AB$276.98 MSRP: $417.00You Save: $140.02 (34%)

Dodge Grand Caravan Electrical Engine Starter

Part Number: 4801839AB$276.98 MSRP: $417.00You Save: $140.02 (34%)

Dodge Grand Caravan Starter Motor Reman

Part Number: R4748046AC$130.95 MSRP: $154.00You Save: $23.05 (15%)

Dodge Grand Caravan Engine Starter

Part Number: 4686045AE$177.08 MSRP: $260.00You Save: $82.92 (32%)

Dodge Grand Caravan Starter Motor Compatible

Part Number: 4748046AB$274.75 MSRP: $409.00You Save: $134.25 (33%)Dodge Grand Caravan Starter Motor Reman

Part Number: R4686104$130.15 MSRP: $139.00You Save: $8.85 (7%)Dodge Grand Caravan Starter Motor Reman

Part Number: R4686111AC$221.38 MSRP: $281.71You Save: $60.33 (22%)

| Page 1 of 2 |Next >

1-20 of 30 Results

Dodge Grand Caravan Starter Motor

The Starter Motor is also used in Dodge Grand Caravan primarily to start the operation of the engine through the power derived from the vehicle battery. To accomplish this, the vehicle makes use of an externally mounted solenoid that is connected to the battery to energise the starter motor. The starter has a rotating armature with field coils or permanent magnets; a drive gear also meshes with the engine flywheel each time the ignition is set to START. In the past few years the Dodge Grand Caravan has come with different styles of Starter Motors inclusive of the Gear Reduction start motor for efficiency and torque. As for starters, the OE starters are made for the regular engines and need reinforcement for the high-compression engines, which may cause starters to fail. The enhancements in the ability of the 'Starter Motor' for the Dodge Grand Caravan showcases improvements in technology, to provide a continually proper supply of engined-impetus.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Grand Caravan Starter Motor at great affordable prices. Moreover, all genuine Dodge Grand Caravan Starter Motor come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Grand Caravan Starter Motor Parts Questions & Experts Answers

- Q: How to replace a Starter Motor or Solenoid on Dodge Grand Caravan?A:Disconnect the cable from the negative terminal of the battery. Remove the starter motor. For a Bosch starter, remove the field terminal nut, disconnect the field terminal, and remove the washer. Remove the three solenoid mounting screws. Work the solenoid off the shift fork and detach it from the drive end housing. Installation is the reverse of removal. For a Nippondenso starter, if you're replacing the starter motor or solenoid, disconnect the field coil strap from the solenoid terminal. To detach the starter motor from the gear reduction assembly, remove the two long through-bolts and pull off the starter. To detach the solenoid from the gear reduction assembly, remove the starter, then remove the two Phillips screws from the gear reduction assembly and pull off the solenoid. Installation is the reverse of removal.

- Q: How to Remove the Starter Motor and Solenoid on Dodge Grand Caravan?A:To remove the starter motor and solenoid, start by detaching the cable from the negative terminal of the battery. Then, remove the upper mounting bolt and nut from above. Next, raise the vehicle and support it securely on jackstands. Disconnect the wires from the terminals on the starter motor and solenoid by removing the two nuts. After that, remove the lower mounting bolt and detach the starter. To reinstall, simply reverse the removal process.

- Q: How Can I Diagnose Starter Problems on Dodge Grand Caravan?A:Before diagnosing starter problems, ensure that the battery is fully charged. If the starter motor does not turn when the switch is operated, check that the shift lever is in Neutral or Park for automatic transaxle models. Additionally, make sure the battery is charged and all cables at the battery and Starter Solenoid terminals are clean and secure. If the starter motor spins but the engine does not crank, the over-running clutch in the starter motor may be slipping, requiring replacement, or the teeth on the flywheel/driveplate may be broken. If the solenoid clicks but the starter motor does not operate, the issue may lie with the battery, main solenoid contacts, starter motor itself, or a seized engine. If the solenoid plunger cannot be heard when the switch is actuated, it may indicate a bad battery, burned fusible link, or defective solenoid. To check the solenoid, connect a jumper lead between the battery (+) and the ignition switch wire terminal on the solenoid. If the starter motor operates, the solenoid is fine, and the problem may be in the ignition switch, neutral start switch, or wiring. If the starter motor still does not operate, remove the starter/solenoid assembly for disassembly, testing, and repair. If the starter motor cranks the engine at a slow speed, ensure the battery is fully charged and all terminal connections are tight. If the engine is partially seized or has the wrong viscosity oil, it may crank slowly. Run the engine until normal operating temperature is reached, then turn it off and disconnect the primary wires from the coil or coil pack. Connect a voltmeter positive lead to the positive battery post and the negative lead to the negative post. Crank the engine and take voltmeter readings as soon as a steady figure is indicated, ensuring not to let the starter motor turn for more than 15 seconds at a time. A reading of 9 volts or more, with the starter motor turning at normal cranking speed, is normal. If the reading is 9 volts or more but the cranking speed is slow, the motor is faulty. If the reading is less than 9 volts and the cranking speed is slow, the solenoid contacts are likely burned, the starter motor is bad, the battery is discharged, or there is a bad connection.

Related Dodge Grand Caravan Parts

Browse by Year

2020 Starter Motor 2019 Starter Motor 2018 Starter Motor 2017 Starter Motor 2016 Starter Motor 2015 Starter Motor 2014 Starter Motor 2013 Starter Motor 2012 Starter Motor 2011 Starter Motor 2010 Starter Motor 2009 Starter Motor 2008 Starter Motor 2007 Starter Motor 2006 Starter Motor 2005 Starter Motor 2004 Starter Motor 2003 Starter Motor 2002 Starter Motor 2001 Starter Motor 2000 Starter Motor 1999 Starter Motor 1998 Starter Motor 1997 Starter Motor 1996 Starter Motor 1995 Starter Motor 1994 Starter Motor 1993 Starter Motor 1992 Starter Motor