My Garage

My Account

Cart

Genuine Dodge Ram 1500 Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

28 Universal Joints found

| Page 1 of 2 |Next >

1-20 of 28 Results

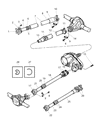

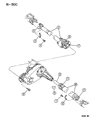

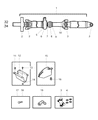

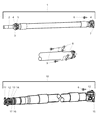

Dodge Ram 1500 Universal Joint

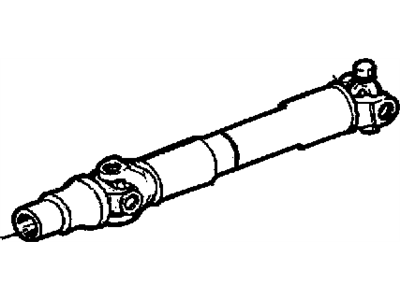

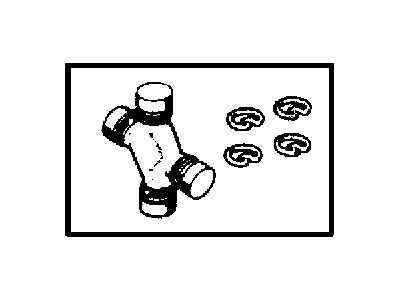

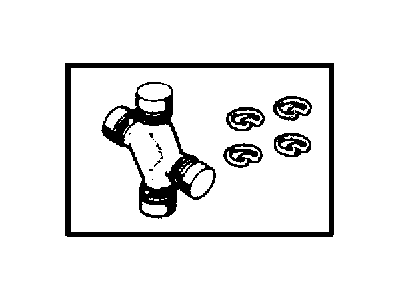

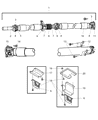

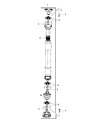

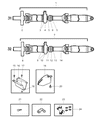

The Universal Joint in Dodge Ram 1500 is one of the essential parts that enable the rotateshaft to swing; at the same time, it transmits power to the axle assembly depending on the road surface. Composed mainly cross with needle bearings in steel cups and incorporating the cross pattern, U Joints are positioned at the front and rear facet of the driveshaft to attach it with the transmission and differential yokes. Though factory U Joints for vehicles are greased when they are manufactured, the U Joints come fitted with grease zerks through which one can periodically add grease. U Joints' signs of deterioration are noise such as: clunking, vibration, and squeaking, in which replacement is required if defects are observed. The example of the universal joint starting from the ancient gimbal till the modern use in the automobiles and industries also affirms the relevance of the subject for the mechanical engineers.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Ram 1500 Universal Joint at great affordable prices. Moreover, all genuine Dodge Ram 1500 Universal Joint come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Ram 1500 Universal Joint Parts Questions & Experts Answers

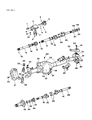

- Q: How to replace universal joints in a driveshaft on Dodge Ram 1500?A:A press or large vise will be required for this procedure. It may be advisable to take the driveshaft to a local dealer service department, service station, or machine shop where the universal joints can be replaced for you, normally at a reasonable charge. Remove the driveshaft. On U-joints with external snap-rings, use a small pair of pliers to remove the snap-rings from the spider. Supporting the driveshaft, place it in position on a workbench equipped with a vise. Place a piece of pipe or a large socket over one of the bearing caps and position a socket against the cap. Use the vise or press to force the bearing cap out. Transfer the sockets to the other side and press the opposite bearing cap out in the same manner. Pack the new universal joint bearings with grease. Position the spider in the yoke and partially install one bearing cap in the yoke. Start the spider into the bearing cap, then partially install the other cap. Align the spider and press the bearing caps into position, being careful not to damage the dust seals. Install the snap-rings. If difficulty is encountered in seating the snap-rings, strike the driveshaft yoke sharply with a hammer. Install the grease fitting and fill the joint with grease. Do not over-fill the joint, as this could blow out the grease seals. Install the driveshaft. For double-cardan U-joints, repeat the above procedure, paying attention to how the spring, centering ball, and bearing are arranged. Both U-joints in the double-cardan assembly must be replaced at the same time, even if only half of it is worn out.

Related Dodge Ram 1500 Parts

Browse by Year

2010 Universal Joint 2009 Universal Joint 2008 Universal Joint 2007 Universal Joint 2006 Universal Joint 2005 Universal Joint 2004 Universal Joint 2003 Universal Joint 2002 Universal Joint 2001 Universal Joint 2000 Universal Joint 1999 Universal Joint 1998 Universal Joint 1997 Universal Joint 1996 Universal Joint 1995 Universal Joint 1994 Universal Joint