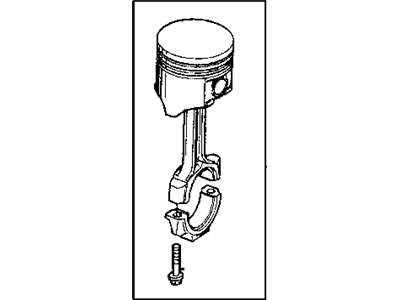

To ensure reliability, purchase Mopar part # 4897660AA Piston. It is sometimes referred to as Chrysler Piston. For Mopar owners with dreams of keeping their vehicles running in prime condition, choosing OEM parts is a smart decision. Meticulously crafted, these parts follow strict factory specifications and are manufactured in top-notch facilities with advanced technologies. Furthermore, they undergo rigorous testing to ensure durability and safety, making them a reliable choice for Mopar owners. This part fits specific Chrysler Cirrus, Sebring, Town & Country models.

MoparPartsGiant.com is a leading supplier of genuine Mopar parts and accessories such as Mopar 4897660AA Piston. Wondering where to find exceptional quality and affordable OEM Mopar parts? You have already come to the right place. Our website boasts a huge selection of genuine Mopar parts at the most economical prices possible. What's more, all parts come with a manufacturer's warranty. For detailed Chrysler parts information, click here.