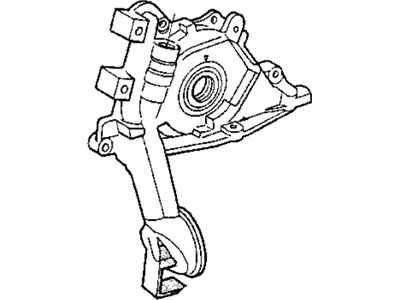

The oil pump pressure relief valve can be serviced without removing the oil pan and oil pick-up tube. Begin by disconnecting the cable from the negative terminal of the battery. Next, remove the timing belt, followed by the oil pan and pick-up tube assembly, and then the crankshaft sprocket. Detach the oil pump assembly from the engine by removing the bolts. If the pump does not come off by hand, gently tap it with a soft-faced hammer or pry on a casting boss. Remove the mounting screws and the rotor assembly cover from the oil pump housing, then pull the inner and outer rotors from the body. Exercise caution with these components, as close tolerances are critical for correct oil pressure; any nicks or damage will necessitate replacing the complete pump assembly. Use a hammer and brass drift to remove and discard the crankshaft front seal from the oil pump housing, and also remove and discard the O-ring seal from the oil pump housing discharge port. Disassemble the relief valve assembly, taking note of the installation of the relief valve piston, and remove the cap bolt, washer, spring, and relief valve. Clean all components, including block surfaces and the oil pan, with solvent, inspecting for excessive wear or damage. Check the oil pressure relief valve piston sliding surface and valve spring for damage, replacing them as a set if necessary. Measure the oil pump rotor dimensions and clearances, comparing the results to the specified values, and replace both rotors if any dimension is out of tolerance. For installation, lubricate the relief valve piston, piston bore, and spring with clean engine oil, then install the relief valve piston with the grooved end first, followed by the spring and cap bolt, tightening the cap bolt to the specified torque. Lubricate the oil pump rotor recess and both rotors with clean engine oil, install the rotors in the body, fill the rotor cavity with clean engine oil, and install the cover, tightening the cover screws to the specified torque. Install a new O-ring in the oil discharge passage and apply anaerobic sealant to the oil pump body sealing surface before positioning the pump assembly on the block, aligning the inner rotor and crankshaft drive flats, and tightening the oil pump bolts to the specified torque. Install the new crankshaft front seal in the oil pump housing, followed by the crankshaft sprocket and timing belt. Install the oil pump pick-up tube assembly and oil pan, then install a new oil filter and lower the vehicle. Fill the crankcase with the proper quantity and grade of oil, reconnect the negative battery cable, and after the sealant has cured according to the manufacturer's directions, start the engine and check for leaks.

Posted by MoparPartsGiant Specialist