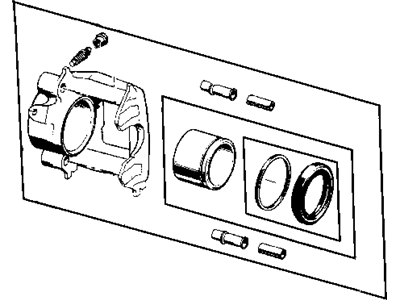

When working on the brake system, it's crucial never to use compressed air for cleaning, and a proper filtering mask should be worn to prevent inhalation of brake dust. Avoid using petroleum-based solvents for cleaning brake parts; instead, utilize brake system cleaner or clean brake fluid exclusively. In the event of an overhaul, it's advisable to explore all available options before commencing the task, as new and factory-rebuilt calipers can be obtained on an exchange basis for added convenience. If the decision is made to rebuild the calipers, ensure a rebuild kit is readily available before proceeding, and always rebuild the calipers in pairs, refraining from rebuilding just one of them. The removal process involves siphoning off a portion of the brake fluid, loosening wheel lug nuts, raising the vehicle, and removing the front wheels. The caliper piston should be bottomed in its bore, and if only the caliper is being removed (without detaching the brake hose), the brake hose inlet fitting bolt should be removed, with new sealing washers used during reinstallation to prevent fluid leaks. During this process, it's essential to have a rag on hand to catch spilled fluid and to wrap a plastic bag securely around the hose end to prevent fluid loss and contamination. Following this, the caliper pins can be unscrewed, and the caliper detached from the vehicle. The overhaul process involves cleaning the exterior of the caliper with appropriate cleaning agents and utilizing compressed air to safely remove the piston from the caliper, taking care to prevent damage. The dust boot is carefully pried out of the caliper bore, and the piston seal is removed using wood or plastic tools to avoid bore damage. The caliper bleeder screw is removed, along with the mounting pin bushings, which should be discarded along with all rubber parts. The remaining components are cleaned, dried with compressed air, and thoroughly inspected for any defects. If surface defects are present on the piston or caliper bore, replacement is necessary. The caliper pins should be checked for corrosion and replaced if needed. During reassembly, lubricate the piston bore and seal with clean brake fluid, ensure proper piston seating, and stretch the dust boot over the piston groove, carefully seating it in the caliper bore. The bleeder screw is installed, new inner and outer mounting pin bushings are added, and the caliper pins are inspected for excessive corrosion and replaced if necessary. Clean the sliding surfaces of the caliper and anchor plate, ensuring proper caliper mounting bolt length if applicable. Then, install the caliper, lubricate the mounting pins with high-temperature grease, and secure them to the specified torque. The brake hose and inlet fitting bolt, using new copper washers, are installed, followed by brake bleeding if the line was disconnected. Lastly, the wheels are reinstalled, the vehicle is lowered, and the brake pedal is firmly depressed multiple times to bring the pads into contact with the disc, followed by a thorough check of brake operation before driving in traffic.

Posted by MoparPartsGiant Specialist