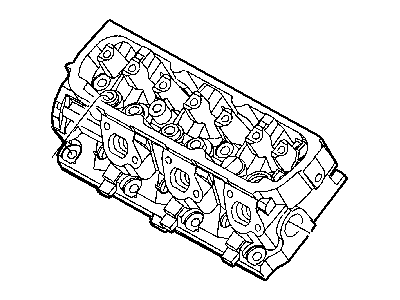

Position the number one piston at Top Dead Center, relieve the fuel system pressure, then disconnect the cable from the negative terminal of the battery. Drain the cooling system and remove the coil packs, spark plug wires, and spark plugs. Remove the intake manifold, covering the intake ports on the manifold and cylinder head with duct tape to keep out debris and contamination. Remove the power steering reservoir and hoses, then the exhaust manifold, noting that the exhaust manifold is easier to remove after the cylinder head is detached. Disconnect the upper radiator hose from the thermostat housing and the electrical connector from the camshaft position sensor, as well as the connectors from the fuel injectors. Remove the timing belt, camshaft sprockets, idler pulley, and rear timing belt cover, followed by the camshafts, rocker arms, and valve lash adjusters. Loosen the cylinder head bolts in the reverse order of the tightening sequence until they can be removed by hand, taking care to note the location of different length bolts. Carefully lift the cylinder head straight up and place it on wood blocks to prevent damage, dislodging it if necessary. Remove all traces of old gasket material from the block and head, using special gasket removal solvents if available, while being cautious not to gouge the aluminum sealing surfaces. Place clean shop rags into the cylinders to keep out debris, use a vacuum to remove contamination, and chase the threads in the engine block with a tap of the correct size. Inspect all threaded fasteners for damage, particularly the cylinder head bolt threads for "necking," and replace any damaged bolts. Have the cylinder head and head bolts cleaned and inspected by a qualified automotive machine shop. For installation, place a new gasket and the cylinder head in position on the engine block, apply clean engine oil to the cylinder head bolt threads, and install them in their original locations. Tighten the cylinder head bolts in sequence, progressing in three stages to the specified torque, and after the third pass, tighten the bolts an additional 90-degrees. Install the rocker arms and hydraulic valve lash adjusters, followed by the rear timing belt cover, camshafts, and camshaft sprockets. Install the timing belt, then slowly rotate the crankshaft manually through two complete revolutions and recheck the camshaft timing marks. The installation of the remaining components follows the reverse order of removal. Refill the cooling system and check fluid levels, then start the engine and run it until normal operating temperature is reached, checking for leaks and proper operation.

Posted by MoparPartsGiant Specialist