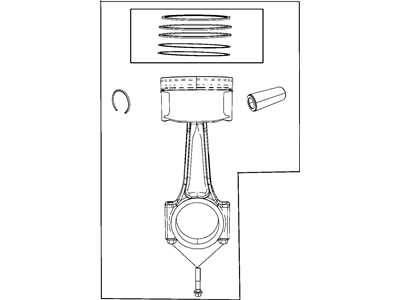

To ensure reliability, purchase Mopar part # 53022257AD Piston. It is sometimes referred to as Piston. The OEM parts should be used when the Mopar owners want to maximize their driving experience. The high-tech factories that produce these parts utilize sophisticated technology specifically designed to meet stringent factory requirements. Additionally, they are thoroughly tested and can thus be used with reliability by Mopar owners. This part fits specific Jeep Commander and Grand Cherokee models.

MoparPartsGiant.com is a leading supplier of genuine Mopar parts and accessories such as 53022257AD Piston. Wondering where to find exceptional quality and affordable OEM Mopar parts? You have already come to the right place. Our website boasts a huge selection of genuine Mopar parts at attractive prices. Further, all parts come with a manufacturer's warranty. For detailed Jeep parts information, click here.