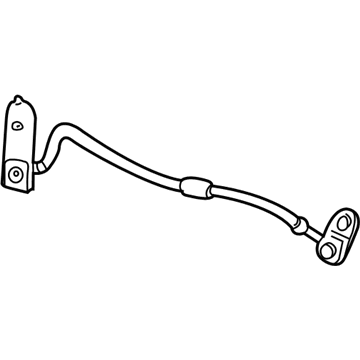

When the vehicle is securely raised on jackstands, thoroughly inspect the rubber hoses that connect the steel brake lines to the front and rear brake assemblies for cracks, chafing, leaks, blisters, or any damage. Use a light and mirror for a complete check, and if any hose shows signs of the mentioned conditions, replace it immediately. To replace a flexible hose, clean the dirt from the hose fittings, and using a flare-nut wrench, disconnect the metal brake line from the hose fitting, being cautious not to bend the frame bracket or line. If the fitting is corroded, apply penetrating oil and allow it to soak before attempting again. Plug the metal line immediately after detaching the hose to prevent leakage and contamination. For rear brake hoses, loosen the hose fitting at the wheel cylinder and remove the hose using a flare-nut wrench. For front brake hoses, unscrew the banjo bolt at the caliper, and after removing the hose, discard the sealing washers on either side of the fitting. Attach the new brake hose to the caliper or wheel cylinder, ensuring to use new sealing washers for front hoses. Tighten the banjo bolt or tube nut to the specified torque. Insert the other end of the new hose through the bracket or loosely attach the fitting/bracket to the vehicle, making sure the hose isn't kinked or twisted, and then fit the metal line to the hose, tightening the hose bracket (if applicable) and the brake tube fitting nut to the specified torque. Check that suspension or steering components don't make contact with the hose, and if necessary, have an assistant push down on the vehicle or turn the steering wheel lock-to-lock while checking for any interference. After installation, check the master cylinder fluid level, add fluid if needed, bleed the brakes, and carefully test brake operation before resuming normal operation. When replacing brake lines, ensure to use steel brake lines from a dealer parts department or auto parts store, avoiding copper tubing. Prefabricated brake lines with flared tube ends and fittings are available, and if bending a line is necessary, use a tubing bender to prevent kinking. Properly support the new line in brackets and provide sufficient clearance from moving or hot components. Tighten the fittings securely, check the master cylinder fluid level, add fluid if needed, bleed the brakes, and carefully test brake operation before resuming normal operation.

Posted by MoparPartsGiant Specialist