×

- Live Chat

- 1-888-511-3595

My Garage

My Account

Cart

Genuine Dodge Nitro Starter Motor

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Starter motors found

Dodge Nitro Starter Motor

The Dodge Nitro Starter Motor is one of the car's subystems that play the vital role of converting electrical energy from the battery into mechanically energy in order to start the engine. In this device, a solenoid is provided as a motor draw which receives the battery energy, and it has an armature and field coils in a starter case with the feature of rotating around. This case, several types of starters include gear reduction starters that forms the drive gear with the engine flywheel. Through the start control circuit comprising of the ignition switch, the starter relay and switch safety the solenoid is pulled thus engaging the small gear of the starter motor with the flywheel of the engine. Hefty engines call for a robust and effective starter that is specifically developed for the application so as to avoid kickback or fail. OE starters may not work in high compression engines since the torque is low when the timing is low.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Nitro Starter Motor at great affordable prices. Moreover, all genuine Dodge Nitro Starter Motor come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Nitro Starter Motor Parts Questions & Experts Answers

- Q: How to check a Malfunction in the starer motor and Starting Circuit on Dodge Nitro?A: If you encounter a malfunction in the starting circuit, don't immediately assume the starter is the issue. First, check the Battery Cable clamps for cleanliness and tightness, inspect the battery cables, and test the battery's condition. Verify the starter motor wiring, mounting bolts, related fuses, ignition switch circuit, starter relay, and the operation of the clutch safety switch or Park/Neutral position switch. If the starter doesn't activate when turning the ignition switch, check for battery voltage to the starter solenoid to ensure it's receiving the correct voltage. If voltage is absent, check the fuses and starter relay. If voltage is present but there's no movement from the starter motor, remove and bench test the starter. If the starter turns over slowly, test the starter cranking voltage and current draw from the battery while observing battery voltage not dropping below 9.6 volts and current draw not exceeding 160 amps. If the starter is receiving voltage but doesn't activate, remove and check the starter motor assembly on the bench, paying attention to the solenoid's operation and pinion drive rotation to diagnose any defects. In rare cases, check for engine seizure before proceeding.

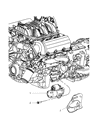

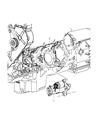

- Q: How to Remove the Starter Motor from a Dodge Nitro?A: Detach the cable from the negative terminal of the battery. Raise the vehicle and support it securely on jackstands. On models equipped with 4WD, detach the left side exhaust down-pipe from the crossover pipe and lower the crossover pipe to allow clearance for removal of the front driveshaft. If equipped, remove the front driveshaft. Remove the heat shield from the starter motor. Disconnect the battery cable and wires from the terminals on the starter motor solenoid. Disconnect any clips securing the wiring to the starter. Remove the two starter mounting bolts and remove the starter from the engine. Note: On 3.7L V6 engines, position the starter so that the front of the starter faces the rear of the vehicle and the solenoid faces downward, then remove the starter by passing it between the exhaust pipe and transmission bellhousing. Installation is the reverse of removal.