×

- Live Chat

- 1-888-511-3595

My Garage

My Account

Cart

Genuine Dodge Ramcharger Brake Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Brake Master Cylinders found

Dodge Ramcharger Brake Master Cylinder

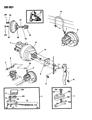

The Brake Master Cylinder for Dodge Ramcharger vehicles is one of the most important brake system parts; the one that works like a translator of the foot force individuals apply on the brake pedal into hydraulic pressure to control slave cylinders. This system uses pistons to pump the fluid to let the operation of calipers or the drum brakes to enable the stopping of the wheels. Master cylinder is normally located at the front of the vacuum power booster and has the separate reserve tank. Dodge Ramcharger vehicles have been employing standard dual circuit master cylinders since the year 1967 so as to have second chance braking irrespective of the hydraulic system collapse. Maintenance is highly recommended as this can avoid the occurrence of leaks, corrosion, and internal failures that may affect the braking mechanism. In general, this Brake Master Cylinder serves a very crucial aspect of the vehicle by providing safe braking to the car.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Ramcharger Brake Master Cylinder at great affordable prices. Moreover, all genuine Dodge Ramcharger Brake Master Cylinder come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Ramcharger Brake Master Cylinder Parts Questions & Experts Answers

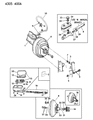

- Q: How Should I Prepare for the Removal of a Master Cylinder on Dodge Ramcharger?A: Place newspapers underneath the brake master cylinder before removal to catch any spilled brake fluid. Disconnect the front and rear Brake Lines from the brake master cylinder and plug the lines and brake master cylinder outlets. On manual brake vehicles disconnect the push rod from the pedal linkage. Remove the mounting nuts and detach the brake master cylinder. Remove the cover and gasket and drain the brake fluid into a container. Remove the plugs from the brake master cylinder outlets and drain the remaining brake fluid. Mount the brake master cylinder in a vise equipped with soft jaws. On aluminum body brake master cylinder, remove the black nylon reservoir by rocking it back-and-forth and pulling up on it. Remove the reservoir-to-housing grommets. On all brake master cylinders except the early Bendix models, remove the front piston retainer screw from inside the rear reservoir or directly beneath the reservoir. On early Bendix brake master cylinders, loosen, but do not remove, the piston retainer screw on the flange. Swivel the retainer tab down to release the rear piston assembly. On all brake master cylinders except early Bendix models, push in on the rear piston and remove the piston snap-ring. On early Bendix models, remove the front piston retaining screw located between the brake line outlets. Remove the rear piston assembly from the brake master cylinder bore. Tap the open end of the brake master cylinder on the workbench to dislodge the front piston assembly. Remove the front piston and spring from the bore. On cast iron brake master cylinders, install an EZ out or metal screw in the tube seats. Remove and discard the tube seats. Remove the residual pressure valves and springs, if equipped. Remove the rubber cups from the ends of the pistons. On cast iron brake master cylinders, remove the O-ring or seal cup from the second land of the front piston. Clean the brake master cylinder with denatured alcohol or brake system solvent and blow it dry with compressed air. Do not, under any circumstances, use petroleum-based solvents to clean brake parts. Clean the cylinder bore with denatured alcohol or brake system solvent. inspect the bore for score marks and pits. Light scratches and corrosion on the cylinder bore walls can usually be removed with crocus cloth or a hone. However, deep scratches or score marks mean the cylinder should be replaced with anew one. If the pistons or bore are severely corroded, replace them. Always use new piston cups and seals when overhauling a brake master cylinder. All components should be assembled wet after dipping them in brake assembly lube.