×

- Live Chat

- 1-888-511-3595

My Garage

My Account

Cart

Genuine Ram 3500 Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

198 Brake Lines found

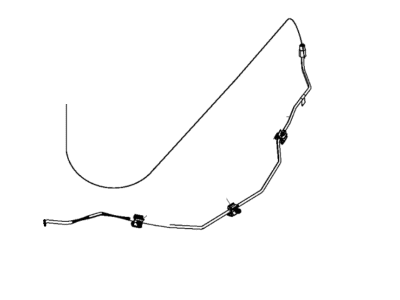

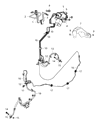

Ram 3500 Tube Assembly-Master Cylinder To HCU

Part Number: 55366059AC$38.60 MSRP: $56.90You Save: $18.30 (33%)

| Page 1 of 10 |Next >

1-20 of 198 Results

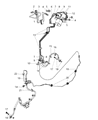

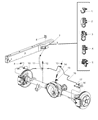

Ram 3500 Brake Line

The Brake Line of Ram 3500 vehicles is capable of transferring brake fluid from master cylinder to brake caliper pistons for the proper working of hydraulic braking. Metal brake lines become susceptible to corrosion and impact which in turn causes the brake fluid leaks and consequently reduction in brake hydraulic pressure. Brake hoses are in much the same boat, they can be damaged physically through wear and tear such as cracks and abrasion and bruises internally that affect the brake system. In cases where replacement is required, there are pre-bent brake line kits, as well as direct replacement brake hoses which are easy to install and very anti-corrosive. Replacing the rubber hoses of brake lines with steel braided ones can result in firm and precise braking especially in acute road conditions.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Ram 3500 Brake Line at great affordable prices. Moreover, all genuine Ram 3500 Brake Line come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Ram 3500 Brake Line Parts Questions & Experts Answers

- Q: How Should I Inspect and Replace Rubber Hoses Connecting Steel Brake Lines on Ram 3500?A: Whenever the vehicle is raised and supported securely on jackstands, inspect the rubber hoses that connect the steel brake lines with the front and rear brake assemblies for cracks, chafing of the outer cover, leaks, blisters, and other damage. These hoses are important and vulnerable parts of the brake system, so the inspection should be thorough. Use a light and mirror to assist in the check. If any hose exhibits any of the above conditions, replace it immediately. To replace the flexible hose, clean all dirt away from the hose fittings. Using a flare-nut wrench, disconnect the metal brake line from the hose fitting, being careful not to bend the frame bracket or line. If the threaded fitting is corroded, spray it with penetrating oil and allow it to soak in for about 10 minutes before trying again. If a fitting nut is frozen, do not force it as it will kink the metal line, which will then need to be replaced. Disconnect the brake hose bracket from the frame and immediately plug the metal line to prevent excessive leakage and contamination. Unscrew the banjo bolt at the caliper and remove the hose, discarding the sealing washers on either side of the fitting. Attach the new brake hose to the caliper, always using new sealing washers. Tighten the banjo bolt to the specified torque. Connect the other end of the new hose, ensuring it is not kinked or twisted. Fit the metal line to the hose or hose fitting, then tighten the hose bracket and the brake tube fitting nut securely. Check that the suspension or steering components do not make contact with the hose. Have an assistant push down on the vehicle while checking for interference with suspension operation. If replacing a front hose, have the assistant turn the steering wheel lock-to-lock while ensuring the hose does not interfere with the steering linkage or steering knuckle. After installation, bleed the brakes, check the master cylinder fluid level, and add fluid as necessary. Carefully test brake operation before returning the vehicle to normal service. When replacing brake lines, use the correct parts and avoid using copper tubing. Purchase steel brake lines from a dealer parts department or auto parts store. Prefabricated brake lines with flared tube ends and installed fittings are available. If bending a line is necessary, use a tubing bender to prevent kinking. When installing the new line, ensure it is well supported in the brackets and has sufficient clearance from moving or hot components. Tighten the fittings securely.