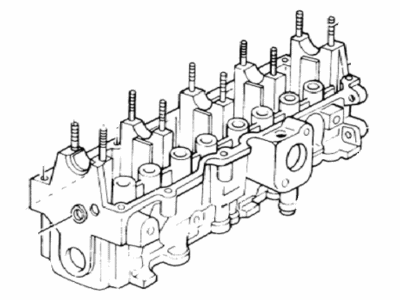

To ensure reliability, purchase Mopar part # 4387614 Head-Cylinder-Partial. It is sometimes referred to as Mopar Cylinder Head. For Mopar owners with dreams of keeping their vehicles running in prime condition, choosing OEM parts is a smart decision. Meticulously crafted, these parts follow strict factory specifications and are manufactured in top-notch facilities with advanced technologies. Furthermore, they undergo rigorous testing to ensure durability and safety, making them a reliable choice for Mopar owners. This part fits specific Chrysler Laser, LeBaron, Town & Country models. It fits Dodge Caravan, Charger, Grand Caravan.

MoparPartsGiant.com is a leading supplier of genuine Mopar parts and accessories such as Mopar 4387614 Head-Cylinder-Partial. Wondering where to find exceptional quality and affordable OEM Mopar parts? You have already come to the right place. Our website boasts a huge selection of genuine Mopar parts at the most economical prices possible. What's more, all parts come with a manufacturer's warranty. For detailed Dodge parts information, click here.