×

- Live Chat

- 1-888-511-3595

My Garage

My Account

Cart

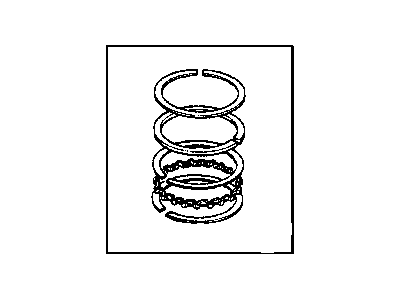

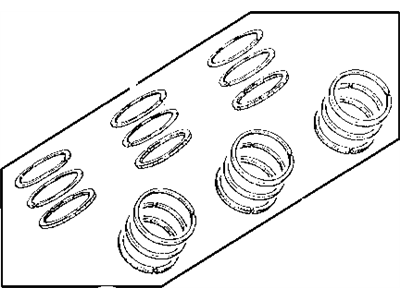

Genuine Dodge Daytona Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Piston Ring Sets found

Dodge Daytona V6-Piston (OUTSIDEIZE 0.75)

Part Number: MD104925$65.93 MSRP: $97.45You Save: $31.52 (33%)

Dodge Daytona Piston Ring Set

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Daytona Piston Ring Set at great affordable prices. Moreover, all genuine Dodge Daytona Piston Ring Set come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Daytona Piston Ring Set Parts Questions & Experts Answers

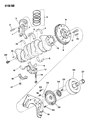

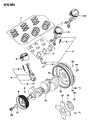

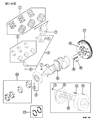

- Q: How should you check and install piston rings before engine assembly on Dodge Daytona?A: Before fitting new piston rings, examine the ring end clearance, to be assured that the piston ring side clearance has been checked and approved. Spread the piston/connecting rod assemblies and the new rings in a manner that ensures that each piston or cylinder is paired with the same piston and cylinder during end gap measurement or during engine assembly. Place the top ring into the first cylinder, aligning it to the cylinder walls by using the piston and then ascertain the end gap and whether or not they meet their specifications by using a feeler gauge. If the gap is incorrect, go on to ensure that the appropriate rings are correct. If the gap is too small, then open it gently with the help of a file, always remembering to file from the outside in. Excess end gap is not too important provided it is more than 0.040-inch (1mm), at this check the rings for correctness. Do the same for every ring in all cylinders, make sure the rings, Pistons and cylinders are compatible. Once the end gaps are checked and corrected, put them on the pistons; oil control ring which is made up of three parts is the first one. Place the spacer/expander into the groove, and put the lower side rail into place with the size mark and manufacturer's stamp in the upper side of the rail In some engines, this is best done with the help of a piston ring installation tool, but in others, it is possible to do this with fingers. When fitting the three components of the oil ring make sure both side rails rotate easily in the groove and that the gaps are positioned at the end. Then the middle ring should be fitted and placed in such a manner that the mark is in the upper part of the piston, and the inner circle slipped into the middle groove of the piston with the help of a piston ring installation tool should not be expanded much. Finally apply the top ring in the same way as to ensure that the identifying mark is facing up, this is followed by the same process for the remaining pistons and rings.