My Garage

My Account

Cart

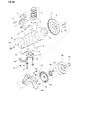

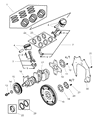

Genuine Dodge Daytona Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

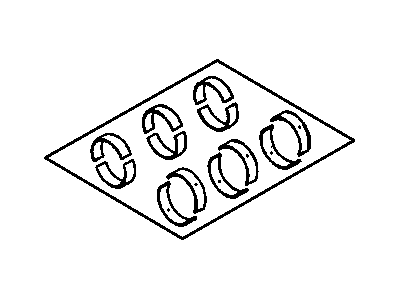

2 Rod Bearings found

Dodge Daytona Rod Bearing

The Rod Bearing in Dodge Daytona cars provides a distinct platform to two other significant and intricate parts, namely the crankshaft and the connecting rods with the aim of facilitating for some form of rotary movement in the engine while at the same time restricting friction. These bearings are mostly plain bearings that may consist of bi-metal or tri-metal and so on. Bearings of the bi-metal type are constructed with an aluminum alloy boundary with silicone harderening to raise seizure strenghth. The found ation bearing structure of the tri-metal bearing is composed of at least a copper alloy layer and a lead-tin-copper overlay for increased strength and fatigue endurance. The Dodge Daytona autos have applied a range of Rod Bearings throughout the years of production with the high-performance models utilizing tri-metal bearings given their advantages in extra durability and the lubrication characteristics. It is therefore possible for Performance Rod Bearings to employ unique surface treatments and manufactured eccentricity to enhance the oil clearance as well as minimize the friction, something that is ideal for high RPM engines. These Rod Bearings need to be installed rightly and must be maintained well for the problem free functioning of the Dodge Daytona.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Daytona Rod Bearing at great affordable prices. Moreover, all genuine Dodge Daytona Rod Bearing come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Daytona Rod Bearing Parts Questions & Experts Answers

- Q: Should the main and connecting rod bearings always be replaced with new ones during engine overhauls, and what factors contribute to bearing failure on Dodge Daytona?A:The main and connecting rod bearings should always be renewed during major overhauls and new ones used but old bearings are useful as an indication of the current state of the engine. It is common to find bearing failure caused by lack of enough lubrication, existence of dirt or other foreign particles, overloading of the engine and corrosion among others; all of which must be corrected before the bearing is put back for reuse. In considering bearings it is necessary to take bearings out from the participating engine parts and align them in sequence to be able to detect problems pertaining to crankshaft journal. Contaminants can find their way into the engine in many ways such as during assembly, in the filters and during machining activities and these penetrate the bearing material or cause scoring and gouging. If not kept clean and well maintained, symptoms such as loss of power, rough idle, and stalling are bound to appear, hence, proper cleaning of every part, as well as regular oil and filter changes should be observed. Without lubrication, problems such as excessive heating, overloading, oil leakage or blocked passages will cause severe harm and overheating. Other driving characteristics are also observed to affect bearing life; for instance, low speed, full throttle, will result to high loads that pushes out oil, short trips causes corrosion because of lack of enough heat. Moreover, bearings can also fail due to oil starvation and trapped debris or due to lack of clearance, which is also attributable to wrong ways of installation of bearings.